Imagine a future where patients no longer have to wait months or even years for an organ transplant. Thanks to advancements in 3D printing technology, this once far-off dream is rapidly becoming a reality. Today, 3D bioprinting has the potential to revolutionize healthcare by offering a pathway to print human tissues and organs in the lab.

At the core of this innovation lies an essential science—chemistry. From the development of bio-inks to the creation of functional, life-sustaining tissues, chemistry plays a pivotal role in making 3D-printed organs possible.

In this post, we’ll dive into how chemistry is shaping the future of organ printing and how this cutting-edge technology is transforming the medical field.

What is 3D Bioprinting?

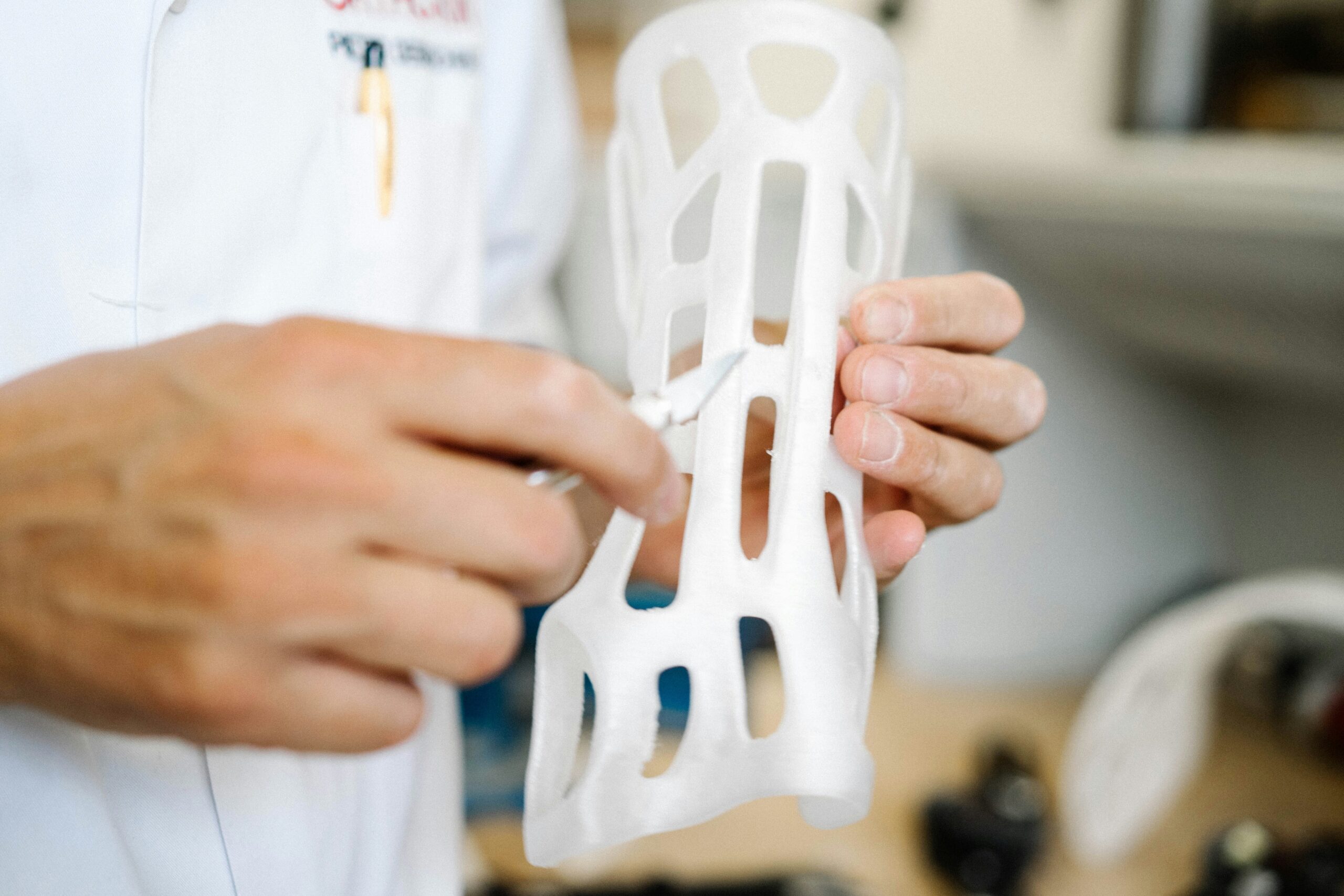

3D bioprinting is the process of creating three-dimensional structures that mimic human tissues, using a combination of living cells, biomaterials, and other bioactive substances. Unlike traditional 3D printing, which involves hard plastics or metals, bioprinting uses “bio-inks” to construct tissues that can grow and function like the real thing.

The process begins with a digital scan of the patient’s organ or tissue. Scientists then use this scan to design a 3D model, which is printed layer by layer. The printed structure is often made using bio-inks containing living cells suspended in a biocompatible matrix, such as hydrogels.

Though bioprinting is still in its early stages, it has already shown great promise, especially in creating everything from skin grafts for burn victims to more complex tissues like heart valves.

The Role of Chemistry in 3D Organ Printing

While the concept of printing organs is exciting, it’s the chemistry behind the scenes that is truly fascinating. Chemistry plays a key role in every step of the bioprinting process, from the development of bio-inks to the stabilization of printed tissues. Let’s break down some of the key chemical innovations that make organ printing possible.

Bio-inks and Biomaterials

At the heart of 3D bioprinting are bio-inks—specialized materials designed to support cell growth and tissue formation. These inks are composed of polymers, proteins, and other chemical compounds that mimic the structure of human tissue.

One of the most commonly used bio-inks is hydrogel, a polymer that absorbs large amounts of water, forming a soft, flexible material similar to the body’s extracellular matrix. Hydrogels can be infused with cells, allowing scientists to print tissues with the physical properties needed to support cell growth.

Designing the perfect bio-ink requires careful consideration of viscosity, biocompatibility, and mechanical strength—all governed by chemical principles.

Crosslinking and Polymer Chemistry

Once a tissue is printed, it needs to solidify into a stable structure. This is where crosslinking comes into play. Crosslinking is a chemical process where individual polymer chains form bonds, creating a strong, interconnected network.

For instance, alginate, a polymer derived from seaweed, is frequently used in bio-inks for its ability to crosslink in the presence of calcium ions. This crosslinking helps the printed structure hold its shape, allowing it to support cells and function like real tissue.

This fine-tuned chemistry ensures that printed organs have the right physical properties and supports the biological environment needed for cell survival and growth.

Vascularization Challenges

One of the biggest challenges in 3D organ printing is creating vascular networks—the intricate web of blood vessels that supply oxygen and nutrients to tissues. Without these networks, cells in larger tissues would die, rendering the printed organ unusable.

Here again, chemistry is leading the way. Researchers are developing bio-inks that can print not just tissue, but also the capillaries needed to nourish that tissue. These advances are bringing us closer to the dream of printing fully functional organs.

Current Progress and Real-World Applications

Although we’re not yet at the stage of printing hearts or kidneys, progress in 3D bioprinting is remarkable. Scientists have already successfully printed simpler structures like skin grafts for patients with severe burns and bladder tissues for people with bladder disease.

Case Study: Printed Skin Grafts

In regenerative medicine, printed skin grafts are game-changers. Traditional skin grafts require healthy donor skin, which can be limited, especially for severe burns. With bioprinting, doctors can create skin directly from a patient’s cells, dramatically reducing the risk of rejection.

Companies Leading the Charge

Several organizations and research institutions are making significant strides in bioprinting. Companies like Organovo are at the forefront, using bioprinting to create functional liver tissues for drug testing. Meanwhile, universities such as the University of Toronto are developing new bio-inks and printing techniques that could one day make full-organ printing a reality.

Future Potential and Challenges

So, what’s next for 3D bioprinting? The ultimate goal is to print fully functional, transplantable organs—hearts, lungs, kidneys, and more. While we’re not quite there yet, researchers are making progress toward this goal every day.

Vascularization and Organ Complexity

Creating complex organs with working blood vessels and nerves remains one of the biggest hurdles. However, advances in vascular bio-inks and scaffold designs are enabling researchers to print more complex tissues, inching closer to fully functional organs.

Ethical and Regulatory Concerns

With any groundbreaking technology comes ethical questions. Should we print organs on demand? How will we regulate the quality and safety of these bioengineered tissues? These are questions that scientists, ethicists, and policymakers must address as bioprinting advances.

Conclusion

3D bioprinting is poised to revolutionize medicine, and chemistry is at the heart of this transformation. From the design of bio-inks to the chemical processes that stabilize printed structures, chemistry is enabling scientists to turn the dream of organ printing into reality.

While challenges remain, the future of 3D bioprinting is incredibly promising. It’s not just a matter of if we will print fully functional organs, but when.

What do you think? Are we close to printing a fully functional heart? Let’s discuss in the comments!

Key Takeaways:

- Chemistry is Central to 3D Bioprinting: From bio-ink formulation to tissue stabilization, chemistry plays a critical role in the success of bioprinting technologies, enabling the creation of functional tissues and organs.

- Bio-inks and Biomaterials: Specialized bio-inks, such as hydrogels, are designed using polymers and proteins to support cell growth and tissue formation, mimicking the body’s extracellular matrix.

- Crosslinking for Structural Integrity: Chemical crosslinking processes are essential in stabilizing printed tissues, allowing structures to hold their shape and support biological function.

- Overcoming Vascularization Challenges: Creating blood vessels in printed tissues is a major hurdle, but advances in bio-inks and chemical scaffolds are paving the way for fully functional organs.

- Real-World Applications in Medicine: Progress is being made with bioprinted skin grafts, bladder tissues, and liver models, signaling the future potential for more complex organ printing.

- Future Possibilities and Ethical Considerations: While printing fully functional organs remains a challenge, developments in chemistry and bioprinting are bringing us closer. Ethical and regulatory questions will shape the adoption of this transformative technology.